Blaenau Ffestiniog - The Town That Roofed The World (Part 2)

After the Ffestiniog Railway opened in 1836, following the discovery of the Merrioneth vein in 1846 an incline was completed in 1848, connecting the railway to the quarry. This enabled the transportation of Llechwedd slate from Blaenau Ffestiniog to Porthmadog in wagons, using gravity to travel down the rail lines to the harbour.

In 1840, the first building to be roofed in Welsh slate in Adelaide, South Australia, was the Friends’ Meeting House; remembering John Greaves’s family’s association with Quakers, it was a most appropriate beginning!

From Porthmadog, slate was exported by sea to destinations around the world; production expanded from 2,900 tonnes of finished slate in 1851 to 7,600 tonnes in 1863. A dedicated wharf was built at Porthmadog to accommodate the fleet of sailing boats for this expanding market.

The great properties of Llechwedd slate were further advanced by the prizes it won at various exhibitions, including the Great Exhibition at Crystal Palace in 1851, where it was awarded a Class 1 Prize Medal. As its popularity grew, it was also given a contract to supply slate to Kensington Palace.

Further successes were achieved at the London Exhibition in 1862, and the Paris Exhibition in 1867; Welsh slate was also promoted in Australia, at exhibitions in Sydney and Melbourne in 1879 and 1880. In 1910, it won the Gold Medal at the Beunos Aires World Fair in Argentina, which resulted in many more orders from South America.

Although mainly used for roofing, slate proved a versatile and durable material; thicker slabs made excellent flooring and worktop surfaces, and memorial headstones. In 1851, during the gold rush in the State of Victoria in Australia, whole houses were made of Welsh slate slabs; what a wonderful material slate is!

John Greaves’ partner, Edwin Shelton, had died in 1848, but Greaves continued to work the Glynrhonwy quarry until 1862. He continued his close association with the Ffestiniog Railway, acting as Treasurer from 1843-47, and twice holding the position of Chairman, firstly from 1843-47 and again from 1850-57.

Very labour intensive, and at the height of its success the slate industry in Wales employed more than 17,000 men, and by the end of the 19th century, their hand-split slates were being exported all over the world.

Today, visitors to Llechwedd Slate Caverns in Blaenau Ffestiniog enjoy an interesting and informative time exploring this fascinating underground world and learning how slate was mined and the slabs then split by hand and prepared for use.

Alicia Enston and Phil Jones are both charismatic and highly experienced Historic Tour Guides.

Alicia is an archaeologist, and apart from acting as a guide for visitors, she is also involved in the developing the educational aspect of the site, creating a fascinating facility for children.

The deep mine

Phil Jones is a musician and song writer, and the fifth-generation member of his family to work at the mine. His family were farriers, looking after the horses, with their skills handed down from father to son, to their grandchildren and to their great grandchildren. They were also blacksmiths, ensuring the tools were kept sharpened and prepared for re-shoeing the horses. Although horses did not work underground, it was important they were kept in fine fettle.

Horses travelled down the line to Porthmadog in “dandy” wagons and, after the slate wagons had been unloaded, they then hauled the empty wagons back up to the mine, ready to be refilled with more dressed slate.

Slate wagons on their downhill journey to Porthmadog

In the 1800s, sleds were used, and when the carts and wagons were loaded, the miners would wrap their hands in the horse’s manes, so they would not lose contact with the horses.

The men were steeped in the life and tradition of the slate mines. Working days were long and hard – the twelve-hour shifts began at 6.00 a.m. and ended at 6.00 p.m., with a half-day on Saturdays. People went to Church or Chapel three times on Sundays; apart from the services, the children also went to Sunday School, where they learned to read and write, so their attendance was not just for faith.

Quarrymen worked in teams of up to 8; first prospecting for the slate, and then agreeing a contract to extract it, they were known as “Bargain Gangs.” “Rockmen” blasted the rock, producing blocks; they worked at an angle of 30 – 40 degrees, and the deeper they went into the mine, the better the quality of slate they extracted, but mining was a very dangerous job.

“Splitters” had the task of cleaving the blocks with a hammer and chisel, and “dressers” completed the work of trimming the slate into the sizes required for roofing.

Other members of the team included a “Rybelwr” – usually a young worker offering to help the gangs, and in the process learn his trade.. “Bad Rockmen” did not mean they were not good at their job! Their task was to remove the unworkable rock from the face of the mine, and the “Rubbish Men” cleared waste from the galleries; this slate formed the waste tips surrounding the quarry.

Rugged scenery surrounding the mine at Llechwedd; and flourishing rhododendrons

Apart from the inherent hazards of mining, men splitting and dressing the slate also fell ill with silicosis, a long-term lung disease caused by breathing in the fine crystalline silica dust produced by working the slate.

Phil Jones gives demonstrations of slate splitting by hand, using the old techniques used by the Romans; in his witty and wonderfully informative talks, giving a clear picture of the miners’ arduous and dangerous work, he makes those early miners come to life.

Phil Jones, delivering his talk and demonstrations

Phil explains: “If the slate is of poor quality, it is a hard job; but with good slate, it’s a pleasure!” Slate splitting chisels are held against the top edge of the slate, and tapped gently into it with a hammer; if it is a good piece, as the slate is cleaved, it will split cleanly, and open up, “like a book.” Then the slate is dressed, to turn it into a roofing slate; again, a very hard, long and laborious – and very dusty – job.

Phil Jones splitting the slate and, below,

In the early days, there was 90% waste of the slate, but now this is reversed, and there is only 10% that is not used.

John Greaves took out a patent for a dressing machine, consisting of two rotating blades, which gave the required chamfered edge for the tiles; a great improvement on the original methods.

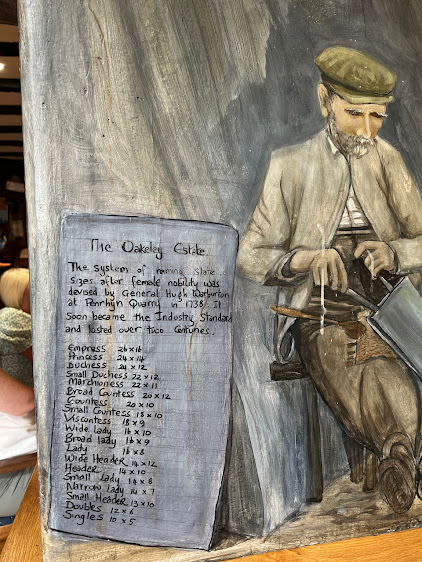

Sizing sticks used by the miners measured 36” x 4 ½”, and most of the slate sizes were given female names. Some were named after noblewomen, for example, Empress, Princess and Duchess, although whether other names - such as Broad Countess, Broad Lady and Wide Lady - caused offence, could be open to discussion!

John Greaves also formed a partnership with Lord Newborough and William Edward Oakeley. William Oakeley was the landowner of Allt-fawr; he inherited the Plas Tan y Bwlch estate in 1868 from the widow of his father’s cousin, who had died childless.

Penrhyn and Dinorwig were the two largest slate quarries in the world, and in 1878, William Oakeley amalgamated them into a single business; the Oakeley mine at Blaenau Ffestiniog was the largest underground slate mine in the world.

When William Oakeley died on 1st February 1912, his coffin was taken by rail from his home at Cliffe House to Blaenau Ffestiniog, and finally by lorry to St Twrog’s Church in Maentwrog. Hundreds of miners from the Oakeley quarry followed the lorry, and William Oakeley was interred in the Church cemetery. His death was reported in The Times, and a report of the funeral procession appeared a few days later.

For visitors to Blaenau Ffestiniog wishing to immerse themselves in history and some wonderfully detailed murals depicting slate miners at work - painted by talented artists - they could do no better than to visit The Oakeley Arms Hotel, a grade II listed building near Maentwrog.

Enjoying a leisurely lunch, or a longer stay at the hotel, surrounded by atmospheric art work, gives people the opportunity to learn and absorb more information about the life of the slate miners of Blaenau Ffestiniog. It has truly earned its title of “The Town that Roofed the World.”

.jpeg)

.jpeg)

.jpeg)